TSMC completes construction on 5nm fab: How this will affect the chip shortage

posted Monday Aug 1, 2022 by Scott Ertz

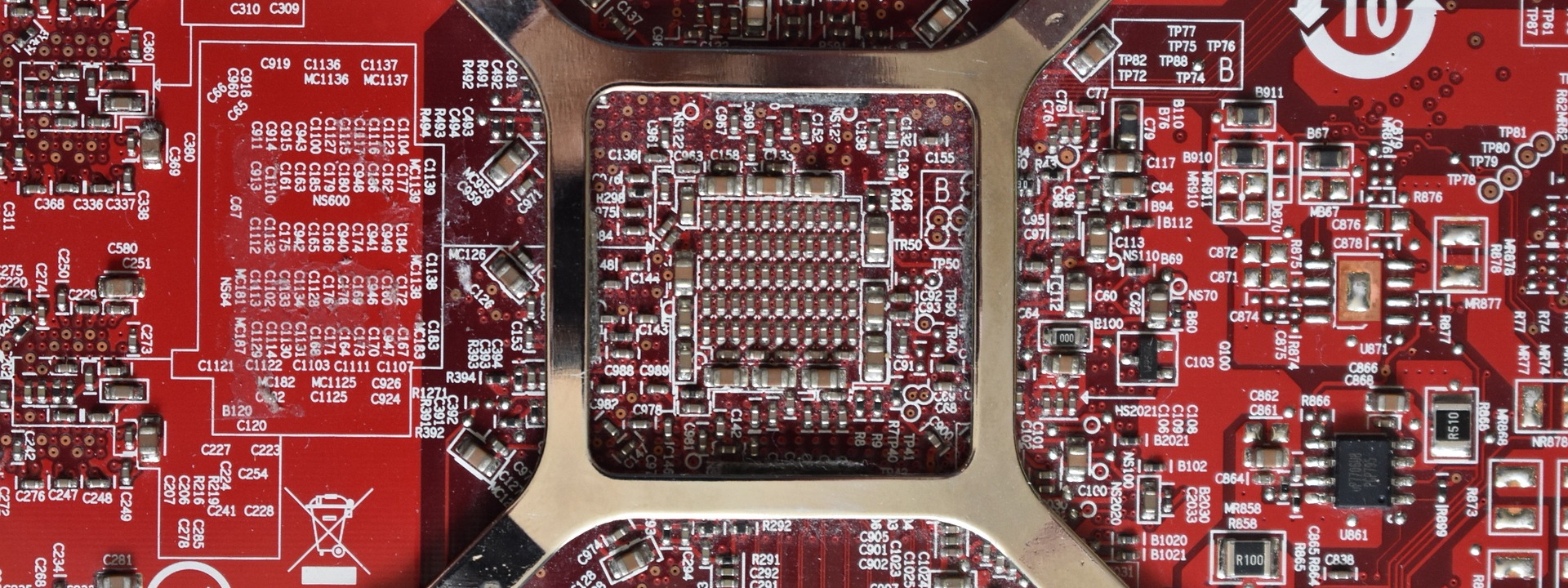

TSMC, the largest chip manufacturer in the world, has completed construction on its newest 5nm fabrication facility. This new fab will help to increase TSMC's production capacity and bring the company one step closer to alleviating the chip shortage that has been affecting most industries across the globe. TSMC is also preparing for a possible invasion of Taiwan, which could further disrupt supply chains and cause even more shortages. With this new facility, TSMC will be better prepared to handle any potential disruptions and continue supplying the chips that the world needs.

What is Taiwan Semiconductor Manufacturing Company (TSMC)?

TSMC is the world's largest dedicated semiconductor foundry, providing advanced IC foundry and manufacturing services to global customers. TSMC operates two 300mm wafer fabs in Hsinchu, Taiwan, and has four 200mm wafer fabs located in the United States, Europe, and China. TSMC also has an advanced 300mm research and development (R&D) facility in Hsinchu. In addition to fabrication facilities, TSMC has a wide range of backend facilities that provide assembly, packaging, testing, and other services to TSMC customers.

The company produces chips for some of the world's largest tech companies, including Apple, Qualcomm, Nvidia, and AMD. TSMC has been crucial in powering many of the devices and technologies that we use today. They also produce chips for embedded systems in cars, industrial applications, and more. TSMC is an important part of the global semiconductor industry and their new fab will help to increase the supply of chips while also preparing for any potential disruptions.

What is the chip shortage?

The chip shortage is a global problem that has been affecting most industries across the world. The main cause of the shortage is the increasing demand for chips, which TSMC and other chip manufacturers have been struggling to keep up with. The second issue is trying to catch up post-COVID lockdowns in Taiwan. The shortage has led to higher prices and longer wait times for many products that use chips, including laptops, smartphones, gaming consoles, and more.

TSMC's new facility will help to increase the company's production capacity and bring it one step closer to alleviating the chip shortage. The new fab will also help TSMC prepare for a possible invasion of Taiwan, which could further disrupt supply chains and cause even more shortages. With this new facility, TSMC will be better prepared to handle any potential disruptions and continue supplying the chips that the world needs.

What are TSMC's plans for the future?

While construction is complete on the facility, the next step is to bring in equipment in order to produce the chips themselves. This will be done in two phases, with the first being the installation of standard essentials, such as plumbing, air conditioning, and ventilation. The second phase will be the introduction of the actual fabrication equipment, like etching and inspection tools.

TSMC's new facility is a step in the right direction, but there is still more work to be done in order to fully solve the chip shortage problem. TSMC and other chip manufacturers will need to continue expanding their capacities and developing new technologies in order to meet the demands of the ever-growing digital world. Only then will we be able to fully overcome this global problem.