General Motors and Subaru halt production amidst chip shortages

posted Friday Sep 3, 2021 by Scott Ertz

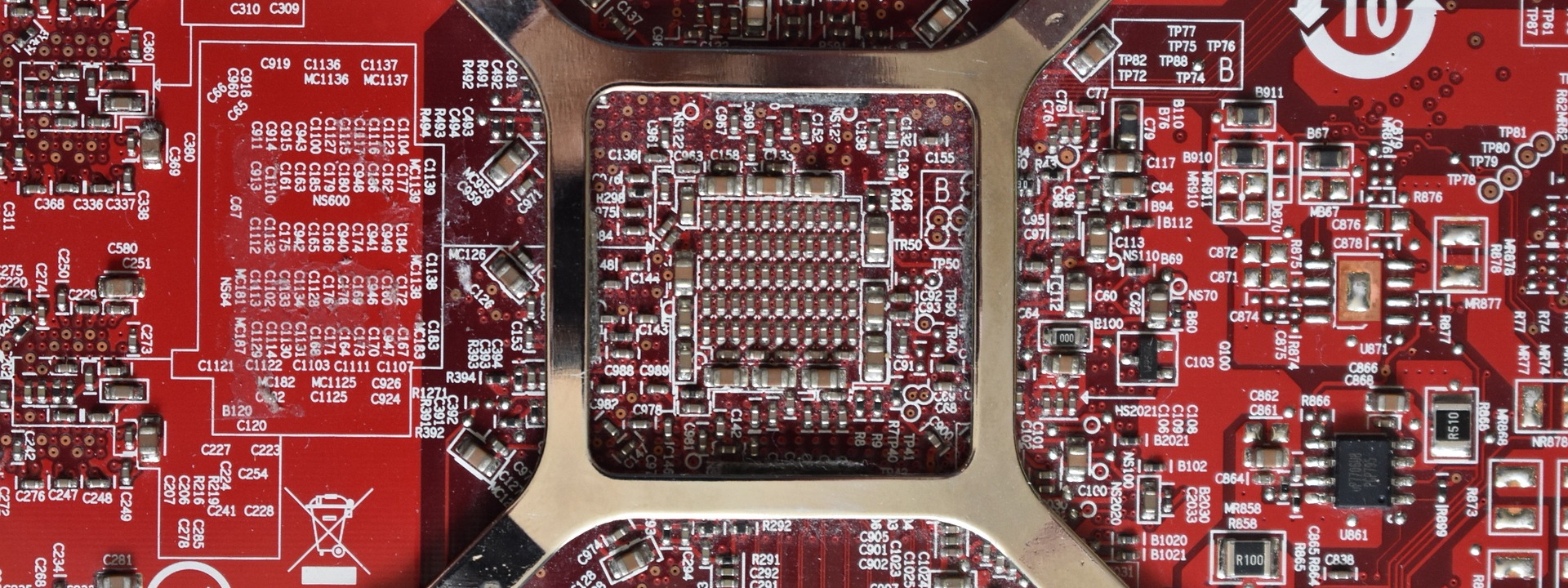

General Motors and Subaru have both announced a temporary production suspension this week, due to chip shortages. General Motors will halt production at nearly all of its facilities in the United States throughout the month of September, while Subaru will shutter its production facilities in Japan for four days. In general, chip shortages have affected nearly every industry - but almost no one has been hit quite as hard as carmakers have.

Subaru does not build all of its vehicles in one country, with some built in the US and others built in Japan. The Japanese production halt, which will take place September 7 through 10, will affect the production of the BRZ, Crosstrek, and Forester. In addition, the automaker also produces some general components in these plants, including engines and transmission.

General Motors, meanwhile, will shut down production of Chevy Silverado and GMC Sierra vehicles at facilities in Fort Wayne, Indiana, and Silao, Mexico next week. It will also idle the Wentzville, Missouri facility, which manufactures the Chevy Colorado and GMC Canyon, for two weeks starting next week. Lansing Delta Township in Michigan, which produces the Chevy Traverse and Buick Enclave, and Spring Hill, Tennessee, which produces the Cadillac XT5, XT6 and GMC Acadia, will see two weeks of downtime this month. Other non-US facilities being affected by the GM suspension include the CAMI plant in Canada, which produces the Chevy Equinox, and the San Luis Potosi facility in Mexico, which produces the Chevy Blazer.

All of these shutdowns will likely put an even bigger strain on the already struggling automotive market. The price for used pickup trucks has gone through the roof in recent months. In some cases, people have offered cash to strangers in public for their trucks (my father has had it happen twice). The existing strain has also been caused by the chip shortage, causing a shortage of new vehicles (especially trucks), which has driven up the price and demand for used trucks. Originally, the auto makers had hoped that the shortage would end quickly, continuing to produce the vehicles to the 99% mark, and then abandoning them in parking lots around the country. Unfortunately, that optimism has not produced a positive result.

Global shortages have been caused by a variety of issues for nearly every industry, many of which were brought upon because of the COVID lockdowns. Production facilities in Taiwan have been particularly affected, which has made the problem even worse. This is because many companies that design their own silicon do not produce the end result themselves. That process is done for many by Taiwan Semiconductor Manufacturing Co. (TSMC), one of the expert companies in the custom chip space. TSMC has had production speed issues, becoming the global bottleneck for many industries, despite currently operating at over 100% capacity in its facilities.

While TSMC originally estimated that it could be several years before things get better, the situation has eased some in recent months. Other manufacturers have stepped in to help produce chips, giving TSMC the ability to catch up on its backlog a bit. Hopefully, we will see the shortage begin to ease a bit within the next year.